Dual-Engine System

JANUS

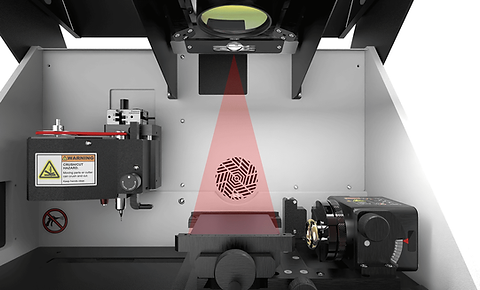

JANUS is the industry-defining MAGIC™-E7 CNC engraving technology and the precision MAGIC™-L3 laser marking system are now integrated into a single machine.

-

Unlimited Creative Freedom

-

MagicEngrave™ - One Software, Total Control

-

True Cost Efficiency

-

Supports CNC scribing and endmill machining

-

Supports laser marking and laser cutting

-

Ring outer & inner engraving supported

(Inner diameter engraving with manual angle adjustment) -

Pen engraving supported

-

Compatible with pendant clamp, anti-curling clamp, tailstock, and CNC cutting clamp

-

Auto positioning via built-in camera

-

Auto focus via probe-based system

-

External I/O ports not supported

Unlimited Creative Freedom

-

Use CNC engraving and laser marking in a single machine.

Without being restricted by a single workflow, you can freely create a wide range of jewelry designs with greater flexibility and creativity.

MagicEngrave™ - One Software, Total Control

-

A dedicated software developed specifically for jewelry applications. Easily operate both CNC and laser processes

from one unified screen for intuitive and efficient control.

-

Less setup. Faster production. An easy-to-use workspace that lets you control both CNC and laser operations from one interface, streamlining tool setup and toolpath generation.

True Cost Efficiency

-

No need to purchase CNC and laser machines separately.

With one system, you can reduce both equipment investment and workspace requirements at the same time.

Automatic Measurement System (Material Height & Tool Length)

-

The integrated material height probe precisely identifies the surface level, allowing users to start machining immediately after clamping, without additional height setting.

-

Automatically compensates for tool length variations caused by tool changes, ensuring consistent engraving depth and machining accuracy.

-

The system automatically detects tool changes and performs real-time measurement and recalibration, allowing seamless operation with multiple tools without manual adjustment.

Built-in Rotary System

-

A fully integrated rotary engraving and machining system comes standard with the machine, eliminating the need for additional options or external attachments.

-

Enables inner and outer diameter engraving on cylindrical objects such as rings, bangles, pens, and mugs, as well as flat materials.

-

Features a rotary tilting structure optimized for laser inner-diameter marking, significantly expanding application versatility.

Multipurpose Detachable Clamp System

-

Multiple clamps can be easily attached and detached, allowing users to select the optimal fixture based on material size and shape. It maximizes efficiency and stability across a wide range of engraving and marking applications.

Cutting & Scribing Dual-Purpose Spindle

-

The head integrates a DC motor and spindle, enabling high-speed rotation of cutting tools such as V-cutters and end mills, while also supporting non-rotational scribing for precision marking.

-

A built-in Z-axis movement control mechanism within the spindle head allows the Z-axis to be locked for cutting operations or released for scribing, enabling quick and intuitive tool selection based on the application.

Built-in L-Tool for Ring & Bangle Inner Engraving

-

A dedicated L-shaped Z tool is integrated into the head for inner engraving of rings and bangles.

-

Inner-diameter engraving can be performed immediately without changing tools, improving workflow speed and reducing setup time.

Certified Safety Viewing Window

-

The safety door is equipped with a certified protective viewing window, allowing operators to monitor the process safely without protective eyewear.

-

The vertical window design provides a wide, unobstructed view of the entire working area during operation.

Camera-Based Positioning System

-

An integrated camera images the laser marking area and sends the material image with size and positional data to the software, enabling precise design, positioning, and scaling directly on the real material image.

Focus Pointer System

-

Due to the invisible nature of laser beams, accurate focusing to a precise point is critical for efficient marking and engraving, particularly for controlled results such as black and white marking.

-

Two focus guide laser pointers indicate the optimal focal point, and the Z-axis is electronically controlled to align with this position, ensuring energy efficiency and consistent marking quality.

Automatic Marking System for Multi-Height Materials

-

The scan head is automatically and precisely controlled to mark multi-level or varying-thickness materials in a single operation, and by inputting the marking surface height values, the system automatically adjusts focus to ensure accurate marking without dividing the job into separate steps.